By EVAN HENERSON

Pictures by Doug Scroggins courtesy of Scroggins Aviation, besides the place famous.

The Scroggins workforce works at assembling the escape vessel by attaching the plastic-formed panels and including the management containers to the inside partitions.

Employee cleansing the floor of a CNC’d 20-lb. Persian board foam half earlier than vacuum-forming it out of ABS sheets.

Go away it to an aviation firm that provides airplanes and helicopters to the flicks to assist Adam Driver’s interplanetary explorer Mills take flight. With out an help from Scroggins Aviation Mockup & Results, the hero of the movie 65 may need discovered himself caught on a doomed planet, sufferer to rampaging dinosaurs, an apocalyptic media bathe or each.

“It simply at all times bothered me [the vehicle cockpits from 1977’s Star Wars], and so the one factor I wish to do is create one thing that was actually distinctive and totally different that regarded prefer it was off-world, so we did simply that.”

—Doug Scroggins, Founder/CEO, Scroggins Aviation Mockup & Results

Thus far, the Las Vegas-based Scroggins Aviation has been creating aviation mockups and results for a spread of film and TV productions with a various slate of credit starting from Iron Man 3 and Manifest all the best way up via Spider Man: No Method Residence and Black Adam.

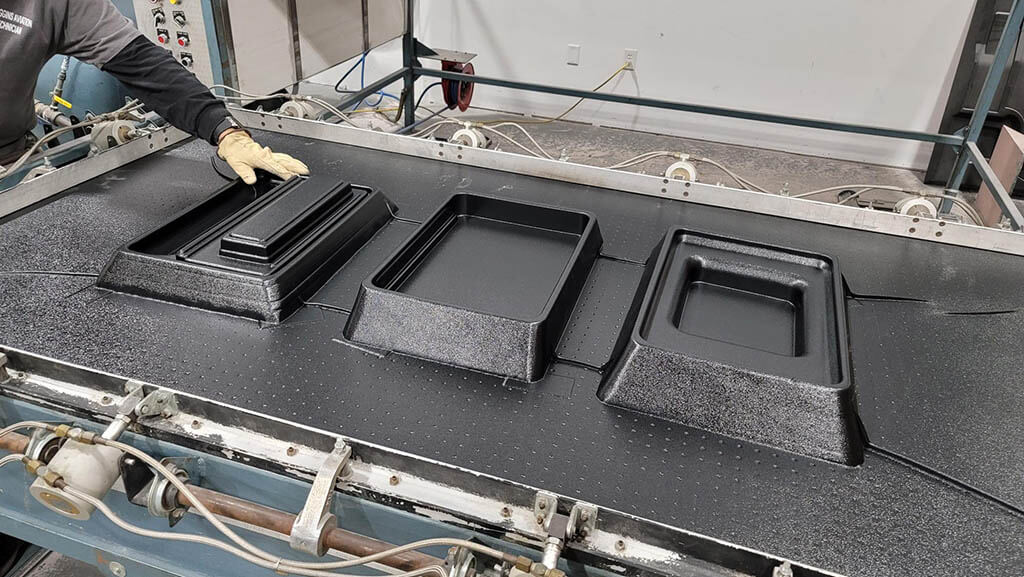

Vacuum-forming the elements.

However whereas they’ve created numerous cockpits and choppers, the one style largely absent from Scroggins’ output has been craft for science fiction movies, with the 2018 Hulu collection The First being – fittingly – the primary time that the corporate was enlisted to mock up an precise spacecraft.

“Now we have been trying to do extra within the science fiction world,” says firm Founder and CEO Doug Scroggins. “For The First, we constructed an Orion house capsule, and the element was simply out of this world. 65 was a significant take-on for us, and I used to be actually honored to do it.”

Inside of the escape vessel reveals plastic panels in place, painted in primer and prepared for colour. Electrical wiring was run to the important thing areas for displays and lighting.

Overview of the escape vessel in its last stage of meeting at Scroggins Aviation’s store.

In 2020, Scroggins was contacted by longtime buddy {and professional} colleague, Kevin Ishioka, the Manufacturing Designer on 65 (which then carried the working title Zoic). The unique request was for parts of the mothership together with the airlock doorways, management containers, panel and one crew seat.

Scroggins takes delight within the element of the interiors of its craft. An unabashed Star Wars fan, Scroggins acknowledges that the Residence Depot-ish look of a number of the automobile cockpits from the 1977 basic have at all times been irksome. “It simply at all times bothered me,” says Scroggins, who added that he would someday like to work on a Star Wars movie, “and so the one factor I wish to do is create one thing that was actually distinctive and totally different that regarded prefer it was off-world, so we did simply that.”

“I’m pondering, ‘Oh, that [the spinning crew seats] adjustments every thing. There goes all of the physics, the engineering and every thing. Now we’re going to want to have people on this factor, they usually’re going to be encapsulated whereas it’s being spun round in all types of various instructions. Now we’re going to must have an engineer log out on this.”

—Doug Scroggins, Founder/CEO, Scroggins Aviation Mockup & Results

Finally, as manufacturing wants developed, Scroggins Aviation was additionally requested to tackle the escape vessel and the 2 crew seats which are featured prominently in the long run of the movie. These seats would truly find yourself holding folks and would wish to have the ability to take the pounding of a motion-based rig or gimbel. Then got here one other wrinkle. The script known as for the rig to be on a gyro platform that will allow the characters to be spun round. And that, says Scroggins, is the place issues began to get fascinating.

Escape vessel onstage, positioned in a particular results rig. (Picture: Kevin Ishioka)

Contained in the escape vessel cockpit, dressed and prepared for filming. (Picture: Kevin Ishioka)

Escape vessel in place, dressed and prepared for filming. (Picture: Kevin Ishioka)

Filming contained in the escape vessel for the scene the place Adam Driver’s and Ariana Greenblatt’s characters try and launch to flee the destruction of Earth. (Picture: Kevin Ishioka)

“I’m pondering, ‘Oh, that adjustments every thing,’” Scroggins recollects. “There goes all of the physics, the engineering and every thing. Now we’re going to want to have people on this factor, they usually’re going to be encapsulated whereas it’s being spun round in all types of various instructions. Now we’re going to must have an engineer log out on this.”

Scroggins ended up constructing three chairs composed of water-jetted metal, fortified by 10-lb. foam. “We vacuu-formed the elements and put the fiberglass in there and created the molds to carry it up,” Scroggins says. “The unique seat was constructed for the straight up-and-down movement, not for the gyro association. In order that one seat you see when Adam Driver is within the cockpit seat and he’s sitting there flying the ship – that’s the seat.”

Artwork render of the escape vessel part that Scroggins Aviation was contracted to construct. (Picture: Kevin Ishioka)

Contained in the escape vessel cockpit, dressed and prepared for filming. (Picture: Kevin Ishioka)

“We created a bible for all the construct. I knew we have been going to have solid members contained in the factor, they usually’re going to roll it on a rotisserie, so I wished to ensure that all of the totally different supplies we have been utilizing could be OK.”

—Doug Scroggins, Founder/CEO, Scroggins Aviation Mockup & Results

The 2 further chairs for the escape vessel have been stable as nicely, but in addition needed to be gentle sufficient so that they might be positioned on a tool that might spin and, in Scroggins phrases, “shake the bejesus out of them.”

The corporate did certainly find yourself consulting with an engineering agency to approve the completed product, one thing that’s not essentially an trade commonplace. “We created a bible for all the construct,” Scroggins says. “I knew we have been going to have solid members contained in the factor, they usually’re going to roll it on a rotisserie, so I wished to ensure that all of the totally different supplies we have been utilizing could be OK.”

Construct for the airlock doorways, higher inside part, metal and wooden inside construction with ABS vacuum-formed panels on the outside.

Construct for the airlock doorways, decrease split-door meeting, metal and wooden inside construction with ABS vacuum-formed panels on the outside.

Ultimate meeting of the doorways added to the set. Three doorways have been constructed for the spacecraft. (Picture: Kevin Ishioka)

“We had [the escape vessel] utterly coated, and we shopped it beneath secrecy. We didn’t need anybody to eyeball it or take any photos.”

—Doug Scroggins, Founder/CEO, Scroggins Aviation Mockup & Results

The construct passed off whereas a lot of the trade was in lockdown on the top of the COVID pandemic. In true across-the-globe collaborative trend, Ishioka was coordinating the movie’s manufacturing design from Japan whereas Scroggins was in Canada engaged on one other film, and the majority of his eight-person workforce was at Scroggins Aviation’s store in Las Vegas. The corporate additionally operates an overflow facility in Mojave, California.

Airlock door added to the set. (Picture: Kevin Ishioka)

When the escape vessel and seats have been completed, they have been loaded on to a flatbed truck that transported them to the manufacturing base in New Orleans in time for the beginning of manufacturing. “We had it utterly coated, and we shopped it beneath secrecy,” Scroggins reveals. “We didn’t need anybody to eyeball it or take any photos.”

Three seats have been constructed for the movie, one the for the mothership and two for the escape vessel.

The seat within the mothership cockpit. (Picture: Kevin Ishioka)

Doug Scroggins with the escape vessel.

Whereas the escape vessel sequences late within the movie showcase the work of Scroggins Aviation most vividly, movie-goers also can see their handiwork throughout the mothership early in 65. Between display panels and contact screens, management panels, airlock doorways and different cockpit units that they constructed and equipped, the Scroggins workforce made certain that no movie-goer would ever accuse this science fiction movie of wanting low-tech.

After seeing how every thing turned out onscreen in 65, Scroggins declared himself each happy and hungry for his agency to take one other journey. “The thrill of seeing the result simply actually made the hairs on my arm begin lifting up,” he says. “This was an authentic movie with a very good premise, and total, on the visible results aspect, it regarded like they nailed it.”