Earlier than we have a look at how digital twins are remodeling manufacturing, we have to perceive the place manufacturing stands proper now.

A World Nonetheless Pushed by Conventional Manufacturing

Regardless of dwelling in an more and more digitized actual world, conventional manufacturing stays important to our financial system. In accordance with a 2021 examine performed by the Nationwide Affiliation of Producers (NAM), manufacturing accounts for an annual 10.94% of U.S. financial output and employs over 12 million folks.

For a very long time, nonetheless, manufacturing has been held again by sure unassailable limitations: Whether or not it’s the continual repairs of costly equipment or adherence to an evolving roster of regulatory compliance tips, optimizing manufacturing facility efficiency has turn into a significant problem.

However all that’s quickly altering with the arrival of a expertise generally known as clever digital twins (or, merely, “digital twins”). On this article, we unpack how digital twins are remodeling manufacturing and why implementing this expertise is integral to your group’s future.

Digital Twins have Remodeled Structure, Engineering, and Building

Learn the way BIM provides designers, builders, and property managers oversight of their constructing

What Is a Digital Twin?

A digital twin is outlined as a precise digital doppelgänger of a bodily object, course of, or setting. In different phrases, it’s a classy software program mannequin that acts as a digital re-creation of a fabric counterpart.

The idea of digital twins was was launched in 1992 and was popularized in manufacturing a number of years later. Nevertheless it wasn’t till 2010 that NASA turned the first group to efficiently undertake the expertise in an effort to refine spacecraft modeling.

Since then, the variety of real-world functions for digital twins has swelled tremendously.

The flexibility to create a digital model of a bodily object that not solely appears to be like the identical however acts the identical has proved indispensable. Subtle algorithms can reliably detect anomalies, anticipate repairs, optimize utilization and lifespan, and simulate efficiency.

Consequently, digital twins have made it potential to beat the ceiling impact that has plagued producers for many years. This digital 3-D duplicate, which might be accessed with a VR headset or desktop, is a promising answer for decreasing downtime and enhancing manufacturing facility effectivity.

How Digital Twins Work

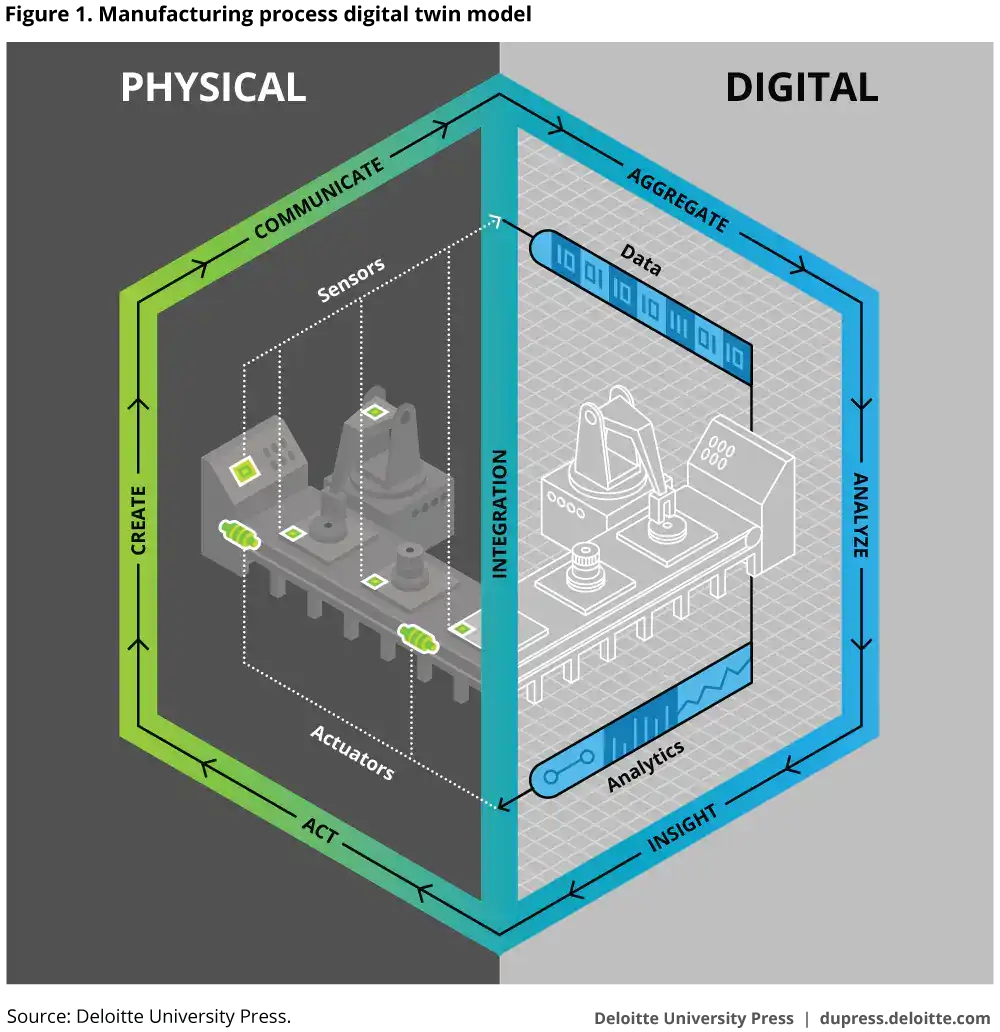

Supply: Deloitte

Technical particulars apart, establishing digital twins is pretty simple.

This primary step is world-building. In manufacturing, for instance, blueprint information a couple of bodily manufacturing facility and its tools is fed right into a 3D mapping program to supply a exact digital setting. Subsequent, real-time displays and sensors are used to extract dynamic efficiency information from equipment.

With the working mannequin full, it’s time to leverage the ability of synthetic intelligence (AI) and machine studying (ML). Superior algorithms set up an operational baseline by “observing” the digital twin and “studying” to tell apart between regular and anomalous efficiency habits.

Historically, most monitoring methods would solely present details about every bit of apparatus in isolation. Within the absence of a holistic method, it shortly turned complicated to handle and straightforward to miss necessary cues.

Digital twins, nonetheless, combination machine information inside its environmental context and in relation to different machines. This produces a consolidated, cohesive, and complete image of your operations at massive, making it potential to derive actionable perception.

How Digital Twins Are Reworking Manufacturing Immediately

To totally grasp the idea of digital twins, we have to see it at work. This requires us to take slightly journey to the gorgeous Bavarian city of Regensburg, Germany. Regensburg is extensively thought of the best-preserved medieval city in Europe. A lesser-known truth is that Regensburg can be residence to not one, however two, monumental BMW manufacturing services.

The primary facility is strictly what you’d count on: a bodily plant that cranks out 800 new vehicles per day. The second facility appears to be like and behaves precisely the identical as the primary—the one distinction is that it exists solely within the digital ether.

Certainly, the BMW manufacturing facility’s digital twin emulates each a part of the manufacturing course of: avatars of staff carrying tools down the manufacturing strains, technicians shaping the steel body of every automobile, and high quality management specialists inspecting each element in minute element.

The digital duplicate, accessed by display or digital actuality (VR) headset and regarded a digital one in actual life, has been an important instrument in decreasing waste, designing advanced technical plans, upgrading infrastructure, and combating local weather change. However auto manufacturing isn’t the one sector singing the praises of digital twin expertise.

In healthcare, digital twins are used to create exact reproductions of inside organs which might be in any other case troublesome to check in actual life. In the meantime, within the aerospace business, protection contractors have leveraged digital manufacturing capabilities to design and prototype next-gen fighter jets for the U.S. Air Drive.

There is no such thing as a scarcity of real-life examples. It’s clear how twins are remodeling manufacturing greater than another piece of expertise for the reason that First Industrial Revolution changed manpower with steam.

Why Digital Twins Are Important to Manufacturing

Sustaining pricey equipment requires a variety of care and a focus. This may be particularly troublesome within the face of ever-changing work circumstances and tight supply deadlines. Regardless of assistance from software program options, many producers have come up towards an impenetrable optimization ceiling—each by way of productiveness and manufacturing instances.

However digital twins are altering the sport by serving to producers optimize effectivity, worth, and innovation at each degree. That is achieved by offering real-time perception into the entire operational state of a manufacturing facility primarily based on its many components and dynamics. The result’s:

- Diminished downtime

- Elevated security

- Elevated throughput

- Predictive upkeep

- Decreased emissions

- Shortened supply cycles

- Decreased manufacturing prices

- Elevated product high quality

It’s no shock that digital twins have grown more and more ubiquitous within the manufacturing business. That is significantly true of organizations coping with costly bodily parts briefly provide, such because the aerospace, healthcare, auto, city planning, and building industries.

Don’t Make the Similar Mistake

When customers have dozens of software program suite selections, what makes the distinction on your customers is interoperability

Trade 4.0 and the Way forward for Digital Twins

The Fourth Industrial Revolution (4IR) guarantees a radical transformation in manufacturing. Clever automation has already united a wide selection of cutting-edge applied sciences which might be ushering within the subsequent paradigm shift, together with:

Digital twins leverage many of those to ship true interconnectedness and decentralized decision-making. And there’s no doubt that this development is right here to remain. The worldwide digital twins market was valued at $3.1 billion in 2020. By 2026, that valuation is predicted to exceed $48.2 billion.

By harvesting information in real-time frames from bodily objects and processes inside the manufacturing facility, steady productiveness enhancements are achieved. This ensures a gradual stream of actionable perception is all the time able to be derived.

Get the Large Image of Your Manufacturing Operations, With Spatial

As we’ve seen, digital twins enhance operational effectivity in a wide range of novel methods. From design and engineering to meeting and repair, this extremely scalable expertise has enabled producers to combine their operations right into a seamlessly interconnected digital community.

Are you able to optimize productiveness, scale back manufacturing instances, and enhance tools life cycles? At Spatial, we will information you thru a whole digital transformation to realize a aggressive edge in your business. Contact us at the moment to find how.

Enhance Performance Whereas Lowering Time to Market…Actually?Spatial’s SDKs assist companies like yours enhance person expertise, extend the applying’s market presence, and increase profitability. Learn the way we may also help you supercharge your subsequent utility. |

Combine Subsequent-Gen Applied sciences With Spatial’s SDKs |