Additive manufacturing has revolutionized the way in which industries do enterprise, and healthcare is definitely no exception. Medical additive manufacturing is taken into account a strong software for creating custom-made medical units and buildings that enhance affected person outcomes and high quality of life.

On this article, we reveal the various methods through which medical additive manufacturing is reworking the medical sector, together with use instances in areas like patient-specific implants, surgical instruments, and prosthetics. You’ll additionally study the advantages of utilizing additive manufacturing in medical discipline functions.

What Is Medical Additive Manufacturing?

Medical additive manufacturing, also referred to as medical 3D printing, is the method of making medical units and buildings utilizing computer-aided design (CAD) and additive manufacturing strategies.

A digital mannequin is shipped to a 3D printer, which creates the thing by increase layers of fabric. The printer can use a wide range of supplies, comparable to polymers, metals, and ceramics, relying on the specified properties of the ultimate object.

Medical additive manufacturing gives many benefits over conventional manufacturing strategies, together with the flexibility to create complicated geometries, scale back affected person wait instances, and enhance surgical accuracy.

Empower Your Finish Customers to Create Customized Medical Gadgets

All of it begins with sturdy SDKs, backed by many years of 3D modeling software program growth.

Examples of Additive Manufacturing in Medical Trade Purposes

Medical additive manufacturing has many functions in healthcare, particularly within the creation of crucial objects comparable to medical units and prosthetics. Let’s take a look at the broad classes.

Surgical Devices and Guides

Additive manufacturing is commonly used to create surgical guides and devices. Merchandise like this have already improved surgical accuracy and decreased the chance of issues. For instance, surgical guides assist a surgeon drill a gap in exactly the suitable location throughout spinal surgical procedure.

Prosthetics

Additive manufacturing can be utilized to create tailored prosthetics. For instance, a 3D-printed prosthetic hand could be designed to match a affected person’s remaining hand. Medical additive manufacturing will also be used to create prosthetic sockets which can be extra comfy and safe than conventional sockets.

Bone and Joint Reconstruction

Constructing upon the concept behind customized matches for prosthetics, medical additive manufacturing permits the reconstruction of bones and joints—together with hip replacements, jaw reconstructions, and knee replacements. 3D printing artificial cartilage can be main the way in which in rebuilding joints.

Synthetic Organs and Tissue

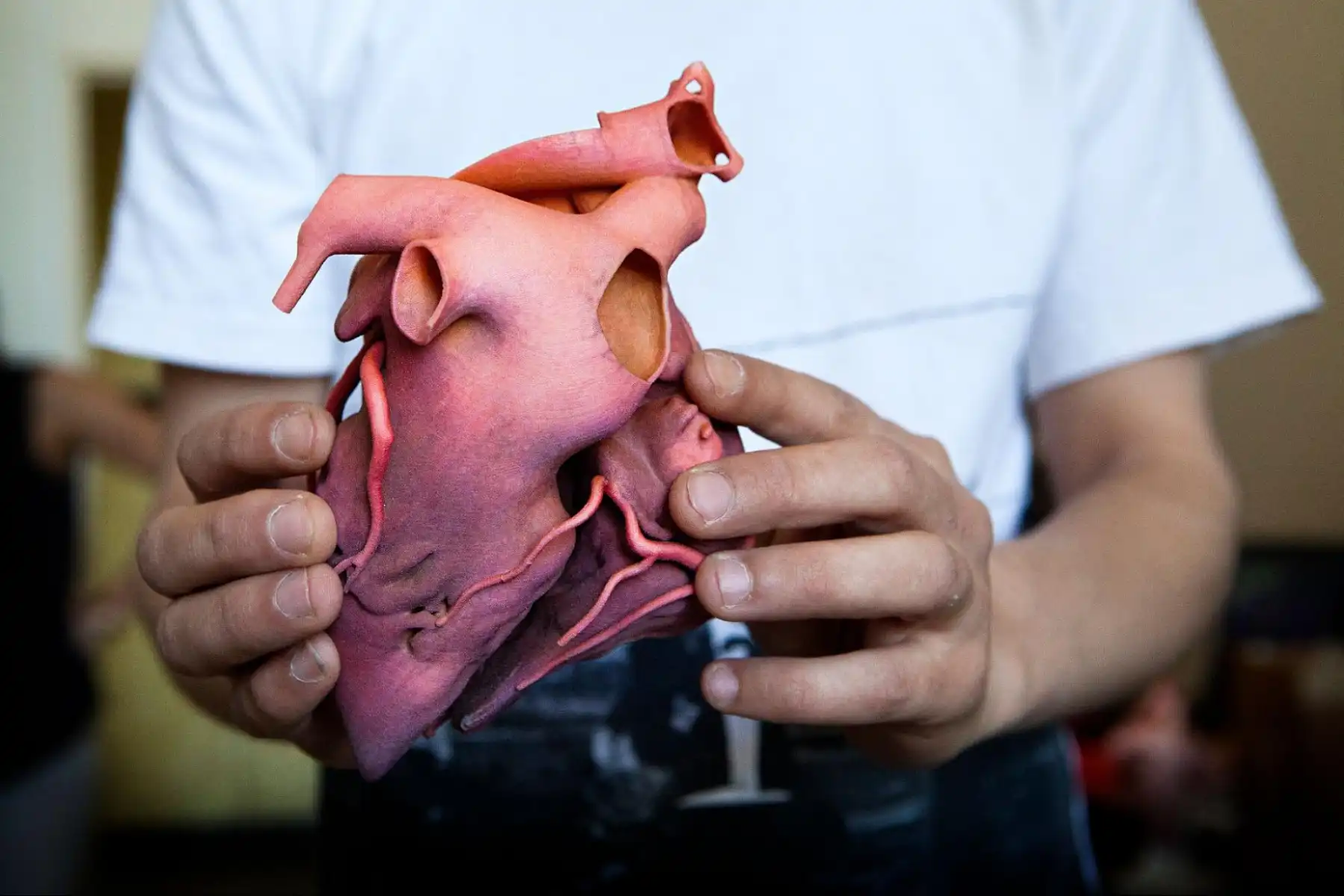

It could come as a shock to some that medical additive manufacturing will also be utilized in bioprinting synthetic organs and tissue—the very constructing blocks of life. These fashions are created with dwelling cells, and the longer term is trying vivid for pores and skin grafting and printing liver tissue to assist handle illness.

As an example, 3D-printed fashions of a affected person’s coronary heart can assist a surgeon plan a posh coronary heart surgical procedure. Fashions are additionally extremely useful in coaching medical college students and residents.

Affected person-Particular Implants

Affected person-specific implants are one of the vital promising functions. These implants are constructed utilizing a affected person’s CT or MRI scan to create an anatomically exact 3D mannequin. The mannequin is then used to design a completely custom-made implant.

Cranial implants, spinal implants, and hip and knee replacements have already proved extraordinarily profitable. In comparison with conventional implants, they’re extra comfy, extra aesthetically pleasing, and might higher mimic capabilities.

How Medical Additive Manufacturing Works

Let’s talk about the essential steps concerned in additive medical gadget manufacturing:

Step 1: Imaging

For patient-specific units, the method begins with medical imaging like a CT or MRI scan. This generates a three-dimensional picture of the affected person’s anatomy.

Step 2: CAD Modeling

Picture information is now transformed right into a digital 3D mannequin utilizing specialised software program known as computer-aided design (CAD). CAD permits the consumer to govern the picture information to create an in depth and correct mannequin of the affected person’s anatomy.

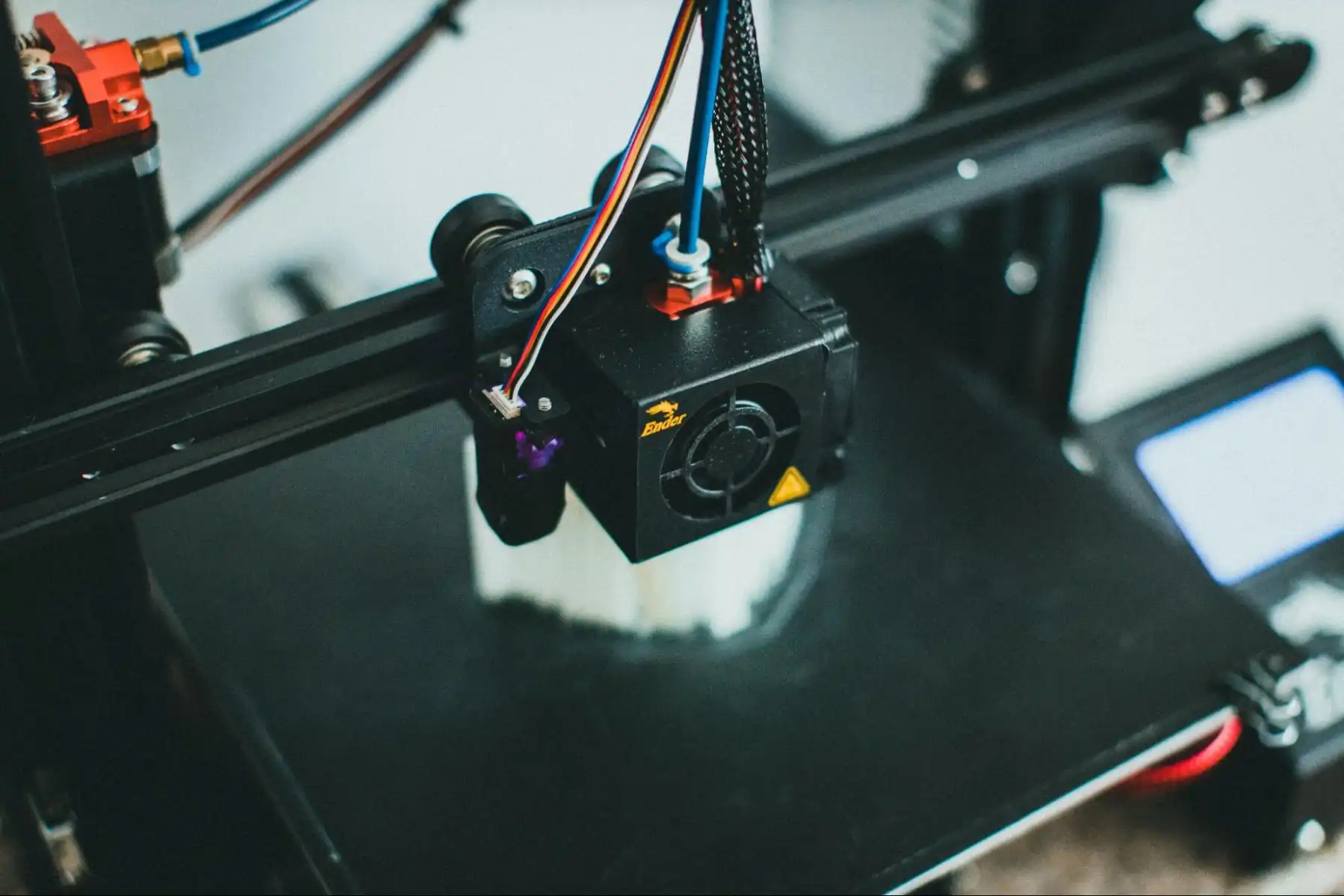

Step 3: Printing

The digital design file is now loaded right into a 3D printer to create the thing. The printer makes use of the design file as a information, depositing materials exactly the place it’s wanted to generate the completed product.

That is accomplished utilizing 3D programs comparable to metallic laser sintering, fused deposition modeling (FDM), stereolithography, and extra.

Step 4: Submit-Processing

As soon as the printing is full, the ultimate product could endure extra processing steps to organize it to be used. This consists of sprucing or sterilization.

Step 5: Implementation

The 3D-printed medical gadget or construction is now prepared to be used.

Keep in mind, the particular steps of the manufacturing course of will range relying on the kind of object being printed, the fabric used, and different elements.

Visualize Higher, Design Higher, Print Higher

Enable your customers to print medical fashions and units seamlessly with Spatial’s SDKs.

Why Enterprises Use Medical Additive Manufacturing

So, why ought to companies like yours think about using medical additive manufacturing? Let’s discover out.

Customization

One of many key causes to make use of medical additive manufacturing is design freedom. Conventional strategies typically contain creating components in massive batches, making constructing custom-made merchandise en masse close to not possible.

By comparability, 3D printing permits you to create customized units and buildings rapidly and effectively—with out counting on costly tooling or molds. That is particularly helpful within the discipline of regenerative medication.

Improved Precision

Additive manufacturing is touted for its unmatched precision. You may create units and buildings with very tight tolerances. That is notably necessary in functions the place accuracy is crucial, comparable to surgical instruments or implants.

Lowered Waste

Additive manufacturing generates considerably much less waste than conventional strategies. Corporations creating extremely regulated or high-value medical merchandise can enhance profitability and scale back compliance danger.

Innovation

Enterprises seeking to discover new design potentialities ought to go for additive manufacturing. This may result in the event of latest medical merchandise, enhance affected person outcomes, and drive innovation.

Quicker Manufacturing

In distinction to conventional means, additive manufacturing is comparatively quick. As an alternative of taking days—and even weeks—to create a custom-made product, 3D printing can full a challenge in a matter of hours.

That is particularly helpful when you think about point-of-care manufacturing. POC manufacturing refers back to the potential to make on-demand medical units and buildings—proper on the website of affected person care. Emergency functions, like catastrophe zones or on the battlefield, are notably promising.

Additive Manufacturing for Medical Gadgets vs. Subtractive Manufacturing

Additive manufacturing and subtractive gadget manufacturing are two approaches to creating medical units and buildings. The latter includes reducing, drilling, or in any other case eradicating materials from a bigger block to create a particular construction. Additive manufacturing of medical units includes increase a construction, layer by layer.

One benefit of additive manufacturing is its design freedom. It permits for exact management over the dimensions and form of a construction—which is crucial to patient-specific medical functions. With subtractive strategies, it’s troublesome and time-consuming to create complicated or customized shapes.

One other upside of additive manufacturing is its potential to scale back waste since solely the supplies wanted to create the ultimate product are used. Subtractive manufacturing includes reducing away materials, leading to vital waste.

Additive manufacturing can be quicker, empowering you to generate complicated buildings in a single construct. Subtractive manufacturing requires a number of steps/setups to attain the identical end result.

Is Your 3D Modeling Software program Prepared for Additive Manufacturing?

Additive manufacturing medical units is a rising discipline with monumental potential to enhance affected person outcomes and rework healthcare. By enabling the creation of extremely custom-made units and buildings, it’s helped medical professionals ship extra customized and efficient remedies.

From patient-matched units to surgical instruments and prosthetics, additive manufacturing know-how in medical discipline functions guarantees to additional innovate the trade. Enhancing the standard of affected person care and ongoing help via medical units is making an increasing number of progress—day-after-day.

For All Your Additive Manufacturing Software program Wants, Belief Spatial

Construct highly effective 3D modeling functions, improve interoperability, and unlock worth to your clients’ workflows with Spatial’s SDKs.

Contact us right this moment to study extra about how we can assist.