For the reason that introduction of mechanization within the 18th-century, manufacturing hasn’t modified all that a lot. Positive—machines have grow to be extra refined, processes have been optimized and scaled, and supplies have improved. However the elementary rules stay the identical. But, extra not too long ago, the benefits of additive manufacturing have fully modified the sport.

Within the early Nineteen Eighties, additive manufacturing started altering how issues had been carried out. This has grow to be notably obvious over the past a number of years, due to huge technological improvements. Right now, producers of all sizes can get pleasure from quicker manufacturing instances, decreased prices, and higher design freedom.

On this article, we’ll briefly go into what additive manufacturing is, the way it works, and the six benefits of additive manufacturing.

Additive Manufacturing: What to Know

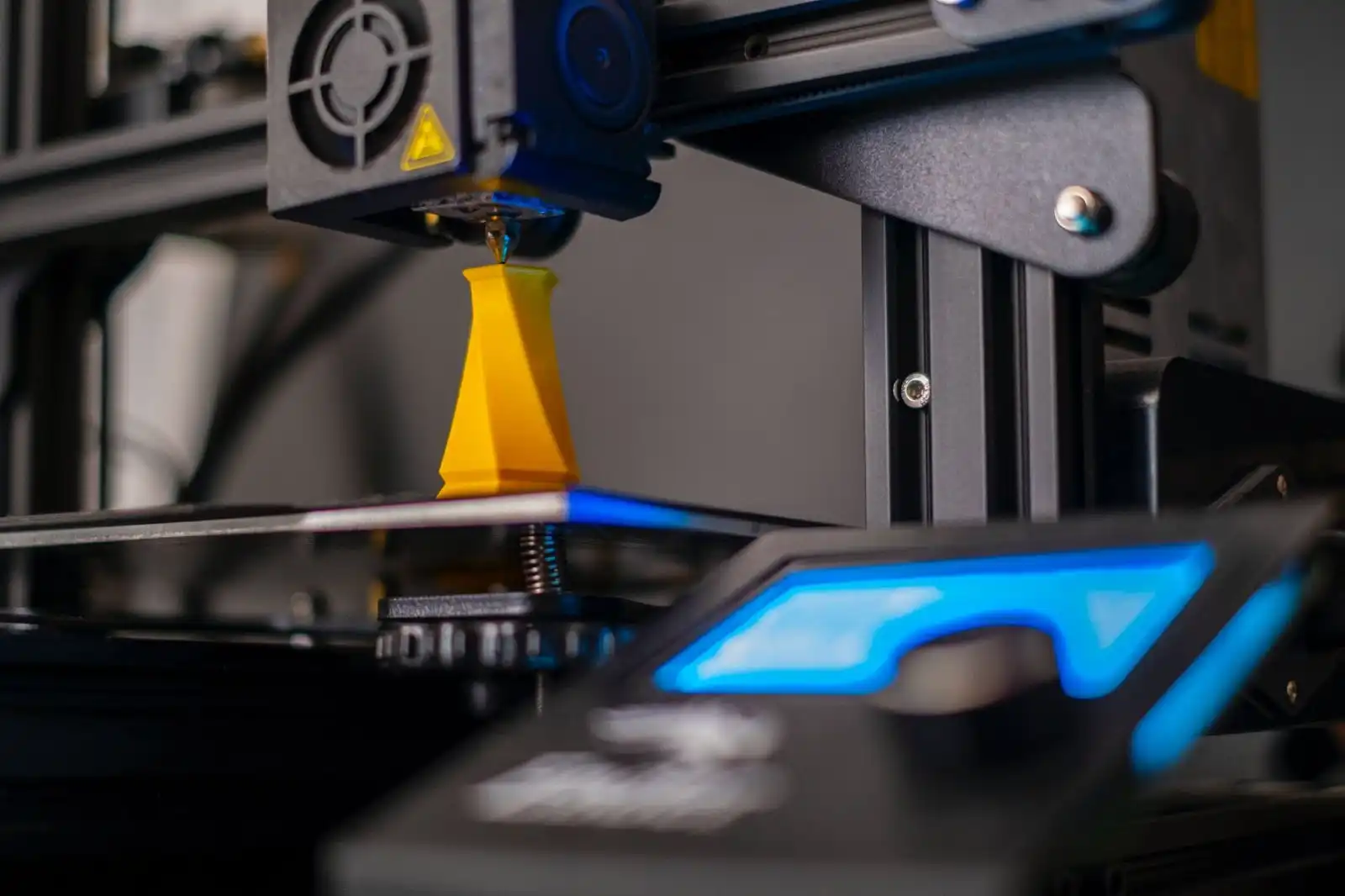

Additive manufacturing could also be a mouthful, nevertheless it’s simply one other identify for what we all know as 3D printing and fast prototyping. It’s the method of making three-dimensional objects by including materials, particle by particle. This stands in sharp distinction to conventional manufacturing strategies, which subtract supplies from the machining or molding course of.

On the coronary heart of additive manufacturing is computer-aided design (CAD) software program. CAD directs machines within the meeting and fabrication of digital fashions. This may be something from a easy baby’s toy to an intricate engineering element.

Additive Manufacturing Doesn’t Have to Be Difficult

Spatial’s SDK options make 3D modeling simpler than ever.

3D printing has already revolutionized the manufacturing area. It has allowed companies to have interaction in on-demand manufacturing and small batch customization; it’s additionally led to a considerable discount in each materials waste and prices, and it has dramatically improved half reliability with exact tolerances.

There isn’t any doubt that as additive manufacturing know-how grows extra refined, 3D printing will grow to be extra ubiquitous. Although it isn’t more likely to substitute conventional manufacturing, it does complement current processes in methods that you could harness at present.

Additive Manufacturing Classes

There are a number of classes of additive manufacturing, every providing its personal distinctive professionals and cons. The tactic you in the end select will rely on the specs of the objects you plan to supply. Let’s take a short take a look at every additive manufacturing methodology.

Created in Japan in 1981 by Dr. Hideo Kodama, stereolithography is the primary 3D printing methodology ever invented. It depends on a photochemical course of, utilizing a laser to treatment photosensitive resin, layer by layer, into an object. In different phrases, cross-linking monomers and oligomers into polymers.

- Fused Deposition Modeling (FDM)

The FDM methodology includes heating a steady filament of thermoplastic materials and extruding it, layer by layer, to construct up the article. It’s also called fused filament fabrication or filament freeform fabrication.

- Selective Laser Sintering (SLS)

SLS makes use of a laser to selectively fuse small particles of additive supplies, like steel or nylon, right into a strong object. As a consequence of its flexibility, SLS can be utilized throughout quite a lot of purposes, from aerospace components and ducting to medical gadget manufacturing.

- Directed Power Deposition (DED)

This methodology includes using a high-powered laser or electron beam to soften and deposit materials onto a substrate. Different names for DED embrace plasma arc melting, direct steel deposition, and laser steel deposition. DED is a typical selection for low-volume productions.

Supply: Unsplash

In any other case referred to as direct ink writing or multi-jet modeling, this methodology makes use of inkjet know-how to deposit droplets of photopolymer or wax onto a platform. A UV gentle then strikes the platform to generate a three-dimensional object from the photosensitive uncooked materials.

Additionally known as powder mattress and inkjet, it makes use of a print head to deposit a liquid binder materials onto a mattress of powders, corresponding to foundry sand, granular ceramics, or sure metals. These are then fused right into a strong object. Binder jetting is often used within the fabrication of sand-casting molds, an alternative choice to injection molding.

Also called laminated object manufacture or selective deposition lamination, this can be a methodology that includes bonding skinny layers of fabric, corresponding to steel sheets or paper, to create an object. Widespread purposes embrace architectural modeling, topographical visualizations, ergonomic research, and extra.

The Prime 6 Benefits of Additive Manufacturing

Now that we perceive what additive manufacturing is and the way it works, let’s think about the core advantages of additive manufacturing.

1. Sustainability

Additive manufacturing provides substantial environmental advantages by enabling on-demand manufacturing. This implies improved materials effectivity, elevated vitality financial savings, and a web discount in your carbon footprint.

2. Price Financial savings

For a lot of enterprise house owners, this is without doubt one of the main benefits of additive manufacturing. Merely put, additive manufacturing processes entail decrease prices than conventional strategies.

That is very true for low-volume manufacturing runs because you’ll solely use the supplies wanted within the printing course of. You’ll by no means have to fret about overproduction.

3. Customizability

In contrast to conventional manufacturing strategies, additive manufacturing provides you the power to create extremely custom-made components and designs. Whether or not it’s essential rapidly improve a small element, fabricate a discontinued legacy half, or tailor a complete manufacturing run to fulfill a selected want, 3D printing makes it a breeze.

Wonderful Product Design begins With the Proper 3D Modeling Expertise

Innovate throughout your complete manufacturing course of—from design to evaluation.

4. Fast Prototyping

Additive manufacturing provides you the ability to supply prototypes quicker than ever earlier than. Not solely does this expedite time-to-market (TTM), it drastically reduces the potential for error. By constructing a number of prototypes in fast succession, you’ll be able to even iron out any manufacturing or design flaws earlier than committing to a manufacturing run.

5. Flexibility and Design Freedom

The flexibility to simply make design modifications and produce advanced geometric shapes is without doubt one of the main attracts of additive manufacturing.

Many firms now use 3D printing to generate advanced parts that had been practically unimaginable to realize utilizing conventional strategies. In reality, the know-how is unmatched relating to creating geometries that maximize stability whereas minimizing weight.

6. Streamlined Manufacturing

In distinction to conventional strategies that require a big stock of supplies, 3D printing permits you to consolidate your meeting right into a single half. This interprets to a discount in stock inventory, carrying prices, and all the related provide chain and logistical complications.

Construct Additive Manufacturing Benefits Into Your Enterprise

There’s little doubt about it: Additive manufacturing will proceed making waves within the manufacturing area. The one actual query is, “how can my enterprise make the most of the highest six additive manufacturing advantages?”

Begin by partnering with a 3D applied sciences professional.

With over 35 years of expertise underneath our belts, we might help you implement and optimize 3D printing capabilities. Our specialists are right here to help you each step of the best way—from technique and integration to lifetime assist.

Contact us at present to be taught extra about how Spatial might help propel your additive manufacturing workflows into the longer term.

Featured Photograph Supply: Unsplash