Hybrid manufacturing is revolutionizing each manufacturing and product design—due to the fast evolution of producing applied sciences. However it may be troublesome for producers, product designers, and engineering companies to maintain up.

3D printing and additive manufacturing, mixed with new subtractive manufacturing applied sciences and extra subtle software program and {hardware}, have pressured producers to repeatedly improve their gear and processes.

Producers are below strain to ship merchandise quicker, cheaper, and higher—making a must automate and join design and manufacturing processes increasingly.

Hybrid manufacturing is one such instance of this convergence, with hybrid manufacturing applied sciences making it attainable to design and manufacture merchandise requiring each additive and subtractive processes. The added bonus? You’re ready to make use of the identical software program suite and machine.

Nevertheless, with this streamlined manufacturing course of comes elevated reliance on knowledge accuracy and visibility, making it essential to have built-in software program that may produce extremely detailed and correct fashions. You must also have the ability to share the related CAD knowledge throughout design and manufacturing groups to scale back the danger of errors within the manufacturing course of.

On this article, we’ll outline what hybrid manufacturing is, go over its advantages over conventional manufacturing processes, take a look at some hybrid manufacturing examples, and discover the significance of unpolluted and correct CAD knowledge in hybrid manufacturing.

Amplify Your Productiveness With Hybrid Manufacturing

What’s Hybrid Manufacturing?

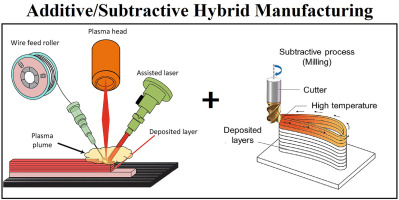

Hybrid manufacturing is a producing course of that mixes each additive manufacturing, also called 3D printing or AM, with subtractive processes, equivalent to CNC machining (milling, grinding, rolling, drilling, and turning), normally on the identical machine.

Hybrid machines normally include a machining device, equivalent to a lathe, which additionally has a directed power deposition (DED) head to deposit wire or steel powder. Different manufacturing methods might mix machining with powder-bed fusion (PBF) or materials extrusion. These machines are referred to as one-step hybrid machines as a result of they’ll carry out subtractive and additive manufacturing in a single course of.

Hybrid methods and one-step hybrid machines provide many benefits in comparison with conventional manufacturing processes.

Advantages of Hybrid Manufacturing Applied sciences

Hybrid manufacturing permits the fabrication of merchandise to be carried out extra effectively, rapidly, and with fewer machines by streamlining the design and manufacturing course of in a unified atmosphere. As a result of a 3D printed half by no means has to depart the construct envelope, there’s a smaller probability of errors.

Hybrid manufacturing creates extra freedom in design and permits for extra intricate and complex components to be created rather more simply by profiting from the pace of 3D printing and the flexibleness of subtractive element work. Generally, components additionally profit from the power to alternate machining and printing to complete detailed inner work, equivalent to cooling channels in injection molds.

(picture supply: Science Direct, 2022)

Examples of Hybrid Manufacturing

Hybrid manufacturing is a comparatively younger know-how, however its use is rising quickly within the automotive and aerospace industries. One frequent instance of hybrid manufacturing is if you 3D print components utilizing steel deposition with a steel powder, adopted by post-processing subtractive machining. This machining has steel milling and sprucing machine instruments to clean the floor of the half.

One other instance, in reverse, is subtractive machining getting used to chop or mill a kind from a chunk of steel, adopted by additive manufacturing that provides skinny coats on this base to finalize the half.

Hybrid manufacturing opens up the potential of combining supplies throughout manufacturing. For instance, an element might require warmth or stress resistance in a single space however not all through the entire half. You’re ready to economize through the use of cheaper supplies to print a lot of the half.

Industries that Use Hybrid Manufacturing

Hybrid manufacturing is well-suited to many industries, however a couple of examples embody:

- Drugs: You possibly can create implants and prosthetics utilizing hybrid machines. Customized-fit gadgets will be created utilizing 3D printing, for instance, after which finalized through detailed milling and sprucing on the CNC machine.

- Aerospace: The aerospace business requires complicated, light-weight however robust components, making hybrid manufacturing important to the business.

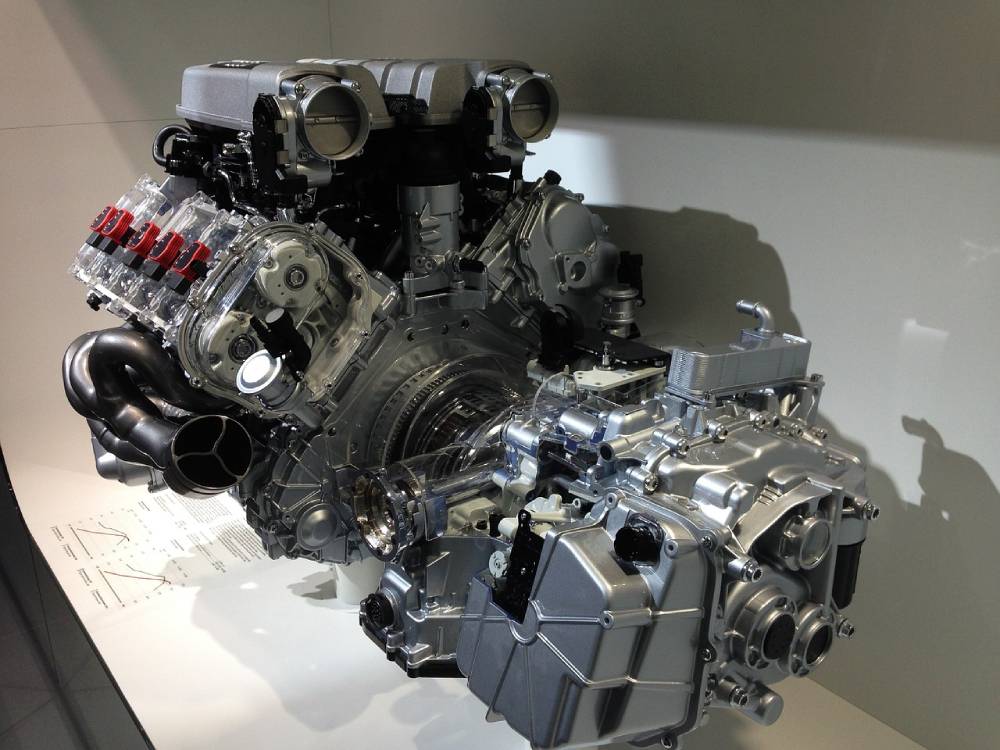

- Automotive: Cars have a large variety of components, many with complicated geometries. Being able to create these components with many fewer machines in one-step processes will help automotive producers lower your expenses.

Varieties of Machines

Varieties of hybrid machines utilized by these industries embody off-the-shelf machines that include each AM and subtractive capabilities, in addition to re-designed subtractive machines which have had AM capabilities added.

The Significance of Clear CAD Knowledge and Fashions in Hybrid Manufacturing

Though there are numerous advantages to hybrid manufacturing, as with all new know-how, it’s essential watch out as you develop new workflow processes. Within the technique of shifting from design to fabricate, CAD knowledge alternate processes might create errors on the file stage, as a file is moved between packages or modeling varieties.

Group members might also introduce errors in the event that they misread knowledge in hard-to-decipher documentation.

It’s extra essential than ever, then, that you simply take note of knowledge cleanliness finest practices and attempt to make clear fashions. This helps guarantee clean transitions between design, 3D printing, and subtractive manufacturing.

A mannequin will be referred to as clear whether it is simply understood by all group members and has exact and correct knowledge. You additionally want the related documentation to interpret the info. You should strictly comply with business and inner requirements, use instruments to make sure that requirements are adopted, and maintain knowledge integrity intact.

How Spatial’s Hybrid Modeling Options Can Assist

To be a magnet for new prospects and provide extra worth to your present prospects, you want a aggressive benefit that places you at the vanguard of producing.

- For software program resellers: It is advisable to transfer away from third-party software program and supply a bundled software program resolution tailor-made to your prospects’ hybrid manufacturing gear. This streamlines the method from design to subtractive processes.

- For gear and half producers: It is advisable to provide single-setup hybrid manufacturing gear as a provider and change to hybrid manufacturing processes in case you’re a components producer. Then, present or undertake tailor-made software program on your hybrid manufacturing gear. This fashion, you may combine workflows and scale back errors.

Construct Your Hybrid Manufacturing Future With Hybrid Modeling

So as to add hybrid manufacturing to your workflow, you want software program that may take several types of fashions with completely different ranges of complexity, and make them suitable with hybrid manufacturing gear.

That is the place hybrid modeling is available in. Spatial’s CGM Modeler SDK empowers 3D software program builders to construct hybrid modeling simply into their purposes. You’re capable of go from importing CAD knowledge from designs to modifying fashions based mostly on machining gear capabilities.

With Spatial’s hybrid modeling SDKs, you may provide mannequin preparation capabilities for additive and subtractive processes in a single software. With these, you’re capable of broaden the scope of your purposes by simply constructing pre-, and post-processing instruments into your hybrid manufacturing platforms, together with:

- Multi-format and modeling kind knowledge import

- Simple mannequin modifications and therapeutic

- Assist definition

- Slicing

- Ending

- Simulation

- Evaluation

- Nesting

- Design comparisons

Hybrid is the Way forward for Manufacturing

Hybrid manufacturing reduces waste, saves money and time, and offers unimaginable flexibility for complicated, personalized components. There will probably be no business untouched by hybrid manufacturing sooner or later—even simply based mostly on its monetary advantages.

Nevertheless, you’re going to want software program with superior options that’s purpose-built for hybrid manufacturing and prevents knowledge integrity points. With out built-in software program options that mix additive and subtractive workflows, manufacturing processes will stay prior to now.

Step into the long run with hybrid manufacturing. Contact us at this time.